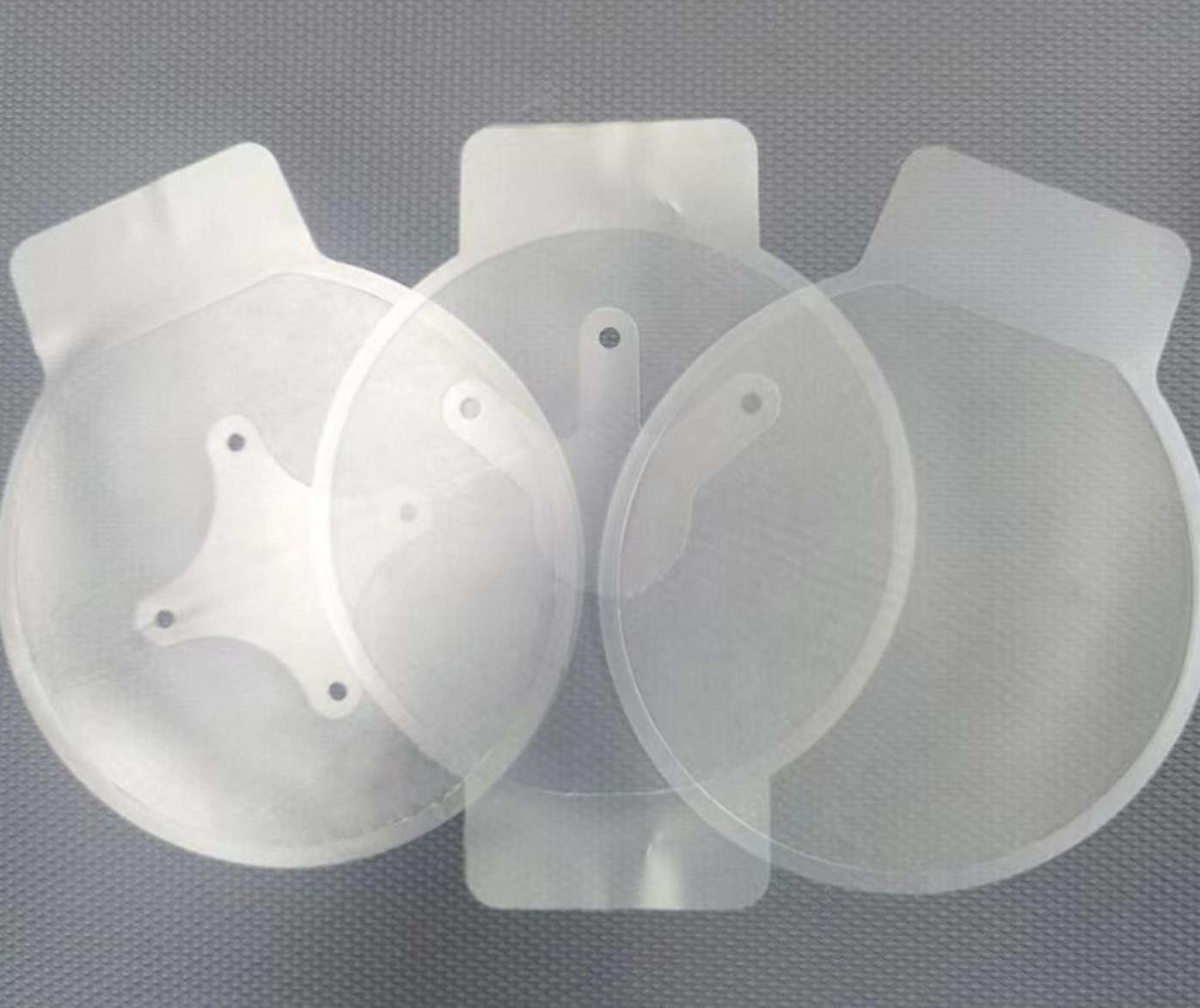

TENS Electrodes

Advantages

Advisor Yiting Xu: Professor/Doctoral Supervisor, Xiamen University.

Her research areas focus on functional polymer materials, multi-element organic and inorganic nanohybrid materials, as well as the design, synthesis, and application of 2D nanomaterials. She directs the process adjustment of hydrogels.

In recent years, SOULBAY has been improving the production process and raw material formula of hydrogel. After almost 8 years’ research, development, and market testing, SOULBAY's hydrogel holds a top position in Chinese market. Compared with Japanese and American hydroge, our products’ properties are almost close, with similar performance properties and cost advantages. Our collaboration with the Chemistry school of Xiamen University has further enhanced our expertise in this field. The company has invested significant material and manpower resources in conducting scientific and technological research and development to enhance the toughness, initial adhesion, adhesion, peel strength, biocompatibility, and other related indicators of hydrogel products. The company has also invested significant material and manpower resources in conducting scientific and technological research and development to enhance the toughness, initial adhesion, adhesion, peel strength, biocompatibility, and other related indicators of hydrogel products. As a result, these indices have now achieved an impressive level of improvement. Now all indicators have achieved the qualities of imported Japanese products, much higher than domestic counterparts.

Soulbay Equipment Department has rich experience in the automation industry and the ability to design and develop independently. TENS Electrodes' main production equipment, such as 7-station circular die-cutting machine and automatic buckling flat die-cutting machine, are all self-developed. Combined with the actual needs of the production process, the company continues to improve the process and synchronize the update of equipment and technology supporting.

Craftsmanship and efficiency

TENS Electrodes' production process and efficiency: Soulbay has built a fully automated circular die-cutter and automatic buckling flat die-cutter production line, utilizing full servo motor control, a complete PLC control system, and a portable integrated operating panel. The precision and speed of our equipment ensure premium quality and timely delivery. Production efficiency significantly exceeds that of traditional semi-automatic or punching and cutting machines, ahead of the industry's overall level. Among them, the single die-cutting machine can produce up to 100,000 pieces per day. The automatic buckling flat die-cutting process is cutting-edge, allowing for mold flexibility to produce special product specifications and one-time completion of TENS Electrodes production, significantly enhancing production efficiency.The production cost of snap-on TENS Electrodes is about 80% lower than the traditional process.

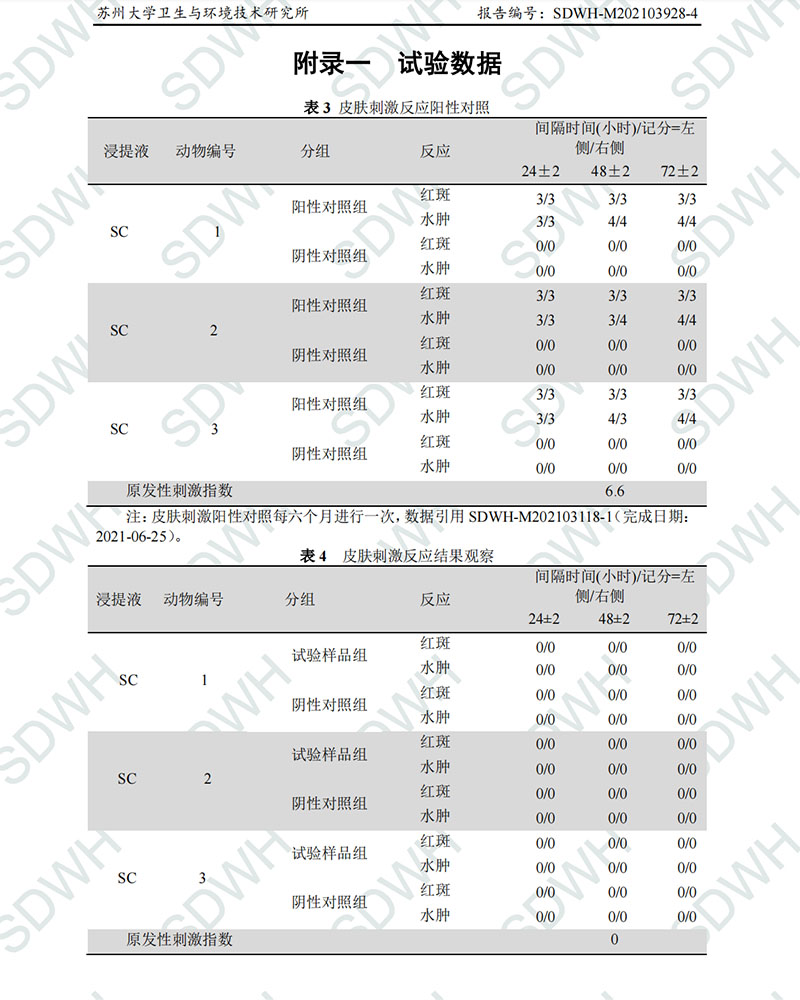

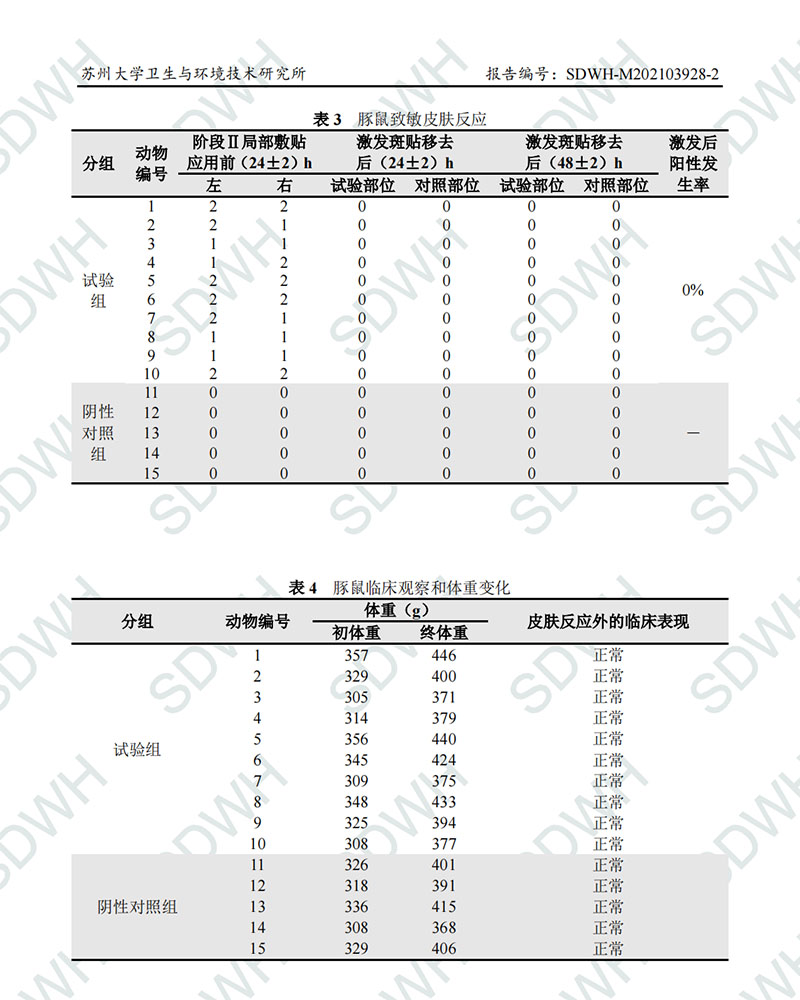

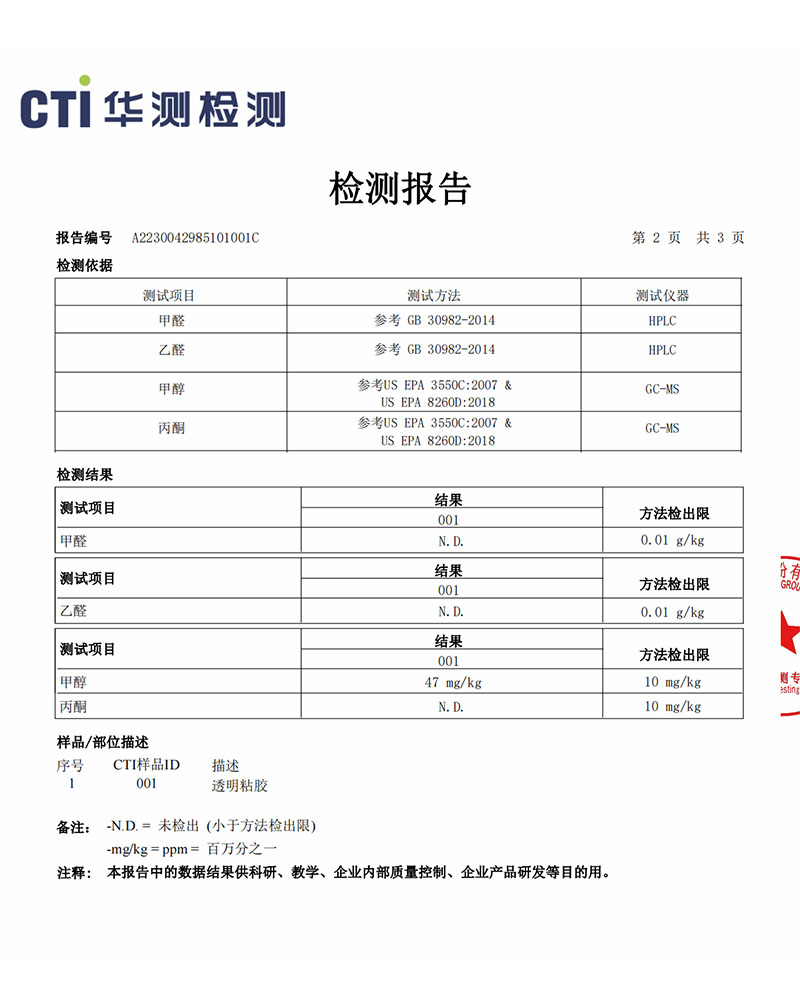

Testing report